Recent and not so recent cases of soil contamination in several states by per- and polyfluoroalkyl substances (or PFAS) and the resulting contamination of groundwater, crops, and animal byproducts (milk, meat, etc.) have added to concerns about the adequacy of regulatory standards for biosolids—sometimes referred to by the broader term sewage sludge.

Biosolids are a byproduct of wastewater treatment made of organic material (similar to compost) that is sometimes applied to land, including agricultural land, in the United States for its nutrient-rich qualities. However, research has demonstrated the pathways through which PFAS can move into wastewater—from wastewater into biosolids, and from biosolids into the further environment—resulting in human exposures. Consequently, these cases and a growing body of research have raised questions about the potential for other cases of PFAS contamination linked to biosolids and how to best prevent and address them through public policy.

As we’ve covered in earlier reports, PFAS are human-made chemicals that have been produced and used in the United States since the 1940s for a variety of industrial and consumer products to make them nonstick, water-repellant, and fire-resistant or suppressive. They are commonly referred to as “forever chemicals” because of their strong carbon-fluorine bonds which make them persistent in the environment and hard to break down. Research, particularly over the last two decades, has also found PFAS to have characteristics of bioaccumulation and toxicity, with exposures being linked to negative human health impacts, including cancers.

Following final federal rulemaking that established drinking water standards for six PFAS earlier this year, and ahead of anticipated new federal rulemaking from the Environmental Protection Agency (EPA) later this year on PFAS in biosolids, this first installment in a multipart blog series outlines what biosolids are and describes their production and use nationally and in New York State.

Subsequent pieces in this series will outline the history and structure of federal biosolids regulation in the United States, as well as the recent federal regulatory commitments, key concerns and cases of PFAS contamination associated with biosolids, and existing state actions with respect to biosolids and PFAS in order to assess the policy landscape and some potential solutions.

What are Biosolids?

The term sewage sludge, understandably, does not tend to evoke excitement or affection, particularly when thought of in connection to food. Yet, sewage sludge and its further byproducts play important roles, not only in our water and waste systems but also in our soil and agricultural systems.

Sewage sludge comes from wastewater (or used water), such as water that flows out of a washing machine or is flushed down a toilet. After water is used by commercial, industrial, or residential sites, that water and any other material that has entered it become wastewater, which then flows to wastewater treatment plants (WWTPs). WWTPs treat or disinfect the wastewater so that some of it can be reused as ‘clean’ water, but those processes also produce other materials. Sewage sludge is the solid and semi-solid byproduct generated by WWTPs or publicly owned treatment works facilities (POTWs) from the processing of wastewater that is composed of water and organic materials.

Biosolids, though sometimes used interchangeably as a term with sewage sludge, refers more specifically in federal regulation to sludge that is further treated (processed or stabilized) and tested to meet certain regulatory standards. There are different processes available that are used to produce biosolids from sewage sludge, such as anerobic and aerobic digestion, lime stabilization, composting, heat, and pelletisation. Like sewage sludge, biosolids are made of water and organic materials—though, despite their name, they are comprised of 94–97 percent water and just 3–6 percent of solids. As a result of the added volume/weight—and the cost therein of transporting liquid biosolids—they are sometimes dewatered into what is referred to as biosolids cake or sludge cake, to have a lower dry weight.

What Do We Do With Biosolids?

Biosolids are primarily “managed” in three ways in the US: they are landfilled, incinerated, or land applied (as a soil amendment or fertilizer).

Landfilling

The EPA has noted that “landfilling biosolids eliminates their reuse potential and is contrary to the EPA national beneficial reuse policy.” In addition, this management option presents other disadvantages including adding to potential odor issues, taking up landfill space that could be otherwise used, contributing to potential groundwater contamination from landfill leachate. It also lends towards the further production of methane, nitrous oxide, and carbon dioxide production as biosolids decompose therein contributing to greenhouse gas emissions and their climate-related impacts. However, the EPA also notes that landfilling has advantages in cases where reuse is not possible. This includes managing biosolids with high levels of metals and other toxic pollutants, when there are constraints on the amount of land available for application, when producing biogas from waste as an energy source, and when it is the “most economical biosolids management solution, especially for malodorous biosolids.”

Incineration

Of the three primary management strategies, incineration (also referred to as thermal oxidation) is the least commonly used in the US. That is in part because there are significant capital and operating costs that depend on the variable price of fuel. Consequently, there are also additional environmental impacts with respect to the use of oil/gas in the process as well as the potential for and need to control air pollutants produced in the process (including particulate emissions and gases like nitrogen oxides, sulfur oxides, and carbon monoxide). Nonetheless, incineration does result in significant volume reduction (up to 95 percent) and carries with it the potential for energy recovery or thermal conversion, capturing heat in the process in order to produce electricity, which can then be used to start the process again.

Land Application

Land application of biosolids is considered a beneficial use by the EPA and other state regulators that helps divert waste from landfills and improves soil quality. Land application can include commercial or residential landscaping (for gardening, parks, or golf courses), forestry, and agriculture. Applying biosolids to land can increase water retention and other beneficial soil characteristics, including adding key nutrients that support plant growth—like nitrogen, phosphorus, and potassium—back into the soil. As such, biosolids can help decrease or replace the use of chemical fertilizers. And, because their organic composition releases these key nutrients more slowly, biosolids can mitigate the potential leaching and impact of nitrogen (and other potential pollutants) on ground and surface water.

How Much Do We Produce?

National Estimates

Getting a full and current picture of sewage sludge and biosolids production and use across the US is challenging. As will be discussed further in subsequent blogs, annual reports are required to be submitted by larger POTWs in 41 states under the EPA’s permitting authority. However, smaller facilities and those in the nine other states (Arizona, Idaho, Michigan, Ohio, Oklahoma, South Dakota, Texas, Utah, and Wisconsin) are not required to do the same.

The Different Types of Ton

| Short Ton | “US Ton” | 2,000 lbs |

| Long Ton | “Imperial (British) Ton” | 2,240 lbs |

| Metric Ton | 2,204 lbs (1,000 kilograms) |

|

| Wet Ton | The combined weight of the mixture of solids and water | |

| Dry Ton | The weight of the solids if all the water was moved | |

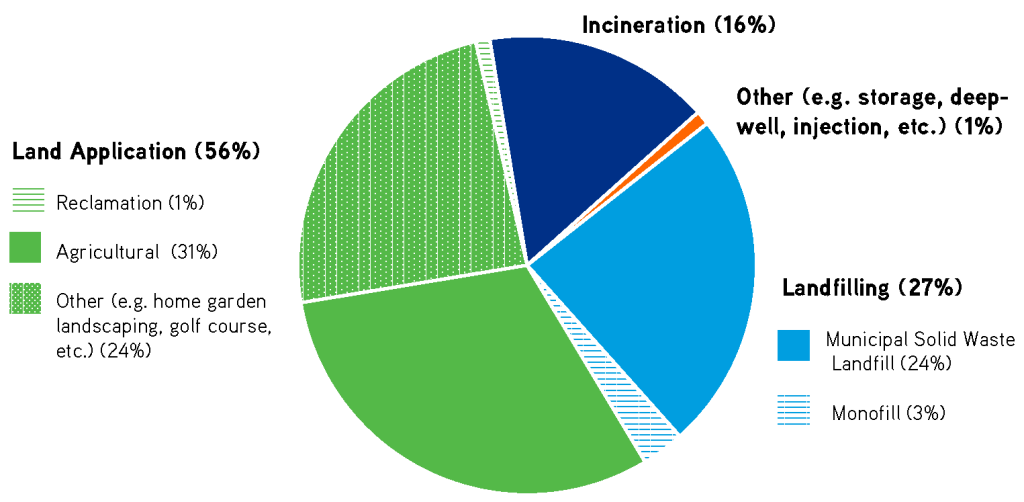

Biosolids are measured in either wet tons, which includes the combined weight of the mixture of solids and water, or dry tons (or dry metric tons), the weight of the solids if all the water was removed. For the facilities the EPA does collect data from,1 in 2022, there were 3.76 million dry metric tons (dmt) of sewage sludge managed, of which 2.12 million dmt, or 56 percent,2 was applied to land (see Figure 1). Of that amount, 1.17 million dmt, or 31 percent of the total, was applied to agricultural land, while the rest was applied to other lands including home gardens, landscaping, golf courses, and reclamation areas. Of the sewage sludge that was not land applied, 1 million dmt or 27 percent was landfilled (mostly in municipal solid waste landfills), and 600,000 dmt or 16 percent was incinerated.

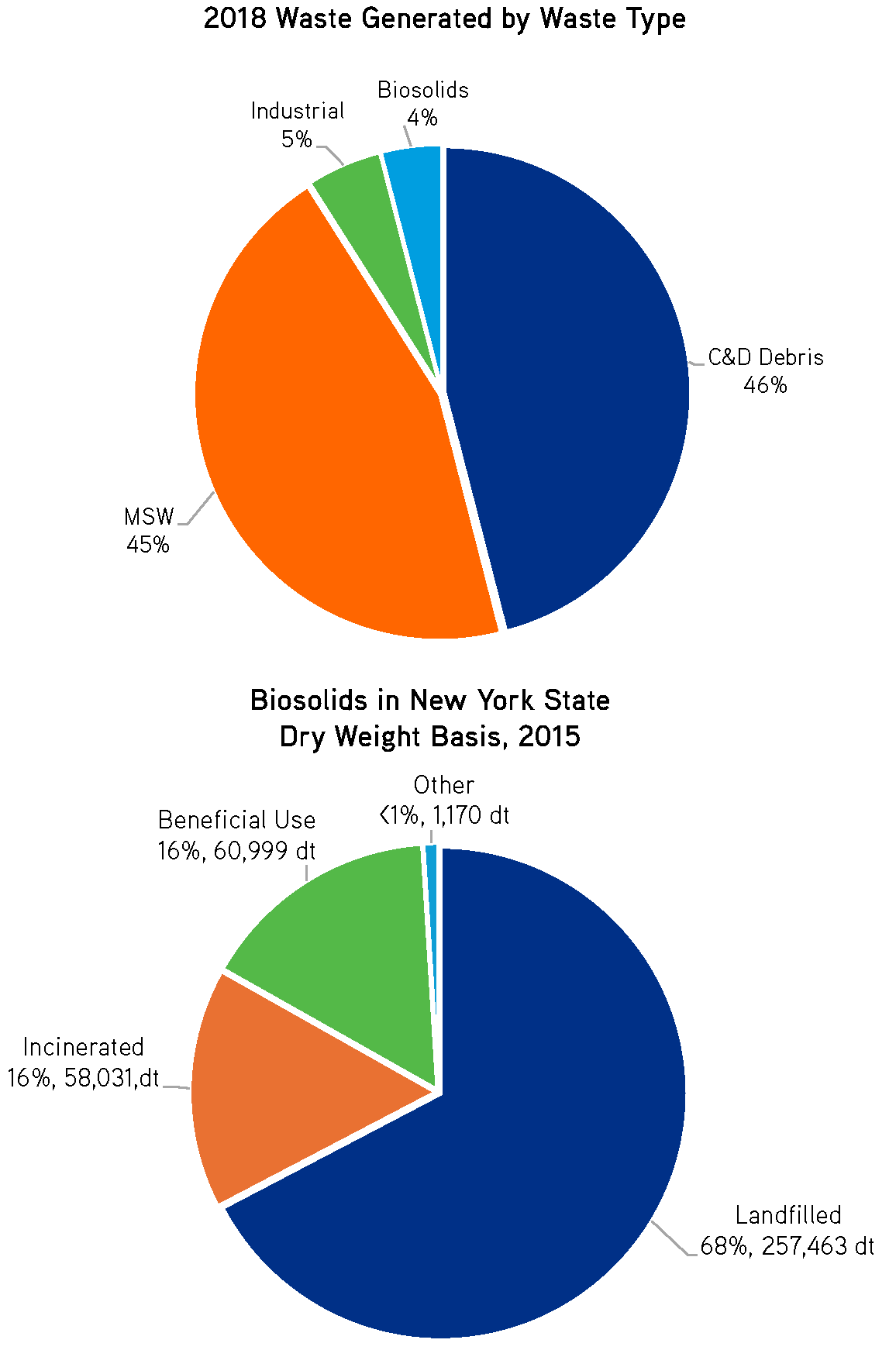

Those reports don’t, however, reflect the total amount of sewage sludge and biosolids produced in the US given that not all producing facilities have reporting requirements. In 2000, the EPA more broadly estimated that there were 7.1 million tons of biosolids generated in total in the United States. Other groups have also attempted to estimate the production and use of biosolids nationally. A report by the Northeast Biosolids and Residuals Association, a nonprofit professional or industry membership association, found that 7.18 million dry tons were used or disposed of in 2004—slightly higher than the EPA’s estimate from four years prior. Their follow-up report based on a 2018 survey of wastewater treatment facilities, carried out by the National Biosolids Data Project, found potential decreased use of biosolids—approximately 5,823,000 dry metric tons of biosolids used or disposed of in the US, with 40 percent used for agriculture, 26 percent used for landfill burial, and 15 percent incinerated.

FIGURE 1. Biosolids Use and Disposal from 2022 Biosolids Annual Reports

SOURCE: Environmental Protection Agency.

New York State Estimates

In New York State, according to the Department of Environmental Conservation (DEC), there are a reported 612 POTWs (also referred to as water resource recovery facilities or WRRFs) that generate approximately 1.3 million tons of biosolids or 375,000 dry tons each year. This makes up 4 percent of the state’s total waste stream (see Figure 2). While the state has supported the beneficial use of these biosolids in its waste management plans, including land application, such uses have decreased significantly in recent years.

According to the most recent publicly available data from 2018, land application declined from approximately 47 percent of biosolids in 2008 to 22 percent in 2018, when 38 percent were landfilled, 19 percent were exported for disposal, and 21 percent were disposed of through combustion. While the beneficial reuse or recycling rate of biosolids in New York declined, over the same time state recycling rates for the total waste stream “increased from about 36% in 2008 to 43% in 2018.”

In dry tons, according to DEC’s 2015 survey data of New York’s POTWs, land application appears even less common in recent(ish) years, with beneficial uses as a whole accounting for 16 percent (including land application, composting, heat drying, and mine reclamation) and landfilling accounting for 68 percent of managed biosolids (see Figure 2). Accordingly, the department’s survey found that 53 percent of facilities (310 of 612 POTWs) landfilled their biosolids. This snapshot appears to represent a very different balance of biosolids management strategies in New York than nationally, where landfilling is much more likely than land application in the state. This bent towards landfilling is due in part to the comparative cost at landfills (though that is variable) and a more concerted shift in practice by New York City, which produces a significant amount of the biosolids in the state, starting around 2010.

FIGURE 2. New York State Biosolids Management

SOURCE: Biosolids Management in New York State.

New York City operates 14 WRRFs within the city as well as seven upstate WRRFs; it also regulates and finances roughly 90 other upstate WRRFs. These facilities treat approximately 1.3 billion gallons of wastewater per day. With respect to the processing of sewage sludge produced from this wastewater, the city has six dewatering facilities, and (at least as of 2021) an agreement with a sewage system in New Jersey for additional processing. To help convey all of the sludge produced, the city has five sludge vessels, a barge, and three sludge force mains (pressurized pipes). Together these systems produce roughly 1,400 wet tons of biosolids per day. In 2018, the city produced 524,307 wet tons of biosolids—roughly 40 percent of the total biosolids produced in the state. The management and use of the biosolids produced by the city has shifted concertedly over the last few decades. Following the enactment of new federal laws in 1992 (which will be discussed further in this series) the city moved towards beneficial reuse through land application but beginning around 2010 this shifted again towards landfilling and by 2018 the city was landfilling a reported 88 percent of its biosolids.

Current waste management plans established by both New York City and New York State, however, seek to reverse course and significantly increase the beneficial reuse of biosolids in order to reduce landfilling (and its associated costs) and aid in reaching city and state greenhouse gas emissions reduction goals. To some degree this reversal is already beginning. In 2020, for example, New York City’s landfilling of biosolids declined to 68 percent—a 20 percent drop from two years prior—with 32 percent being beneficially reused. New York State’s most recent Solid Waste Management Plan (2023) likewise projects that current and planned efforts will result in reversal of existing trends statewide, with a 37 percent recycling rate (beneficial use including land application and other means) by 2030 and a 57 percent recycling rate by 2050.3

But what might the existence of pollutants like PFAS in biosolids mean in the context of these practices and shifting trends? Both for the millions of tons of biosolids landfilled as well as for those that states, localities, and residents have beneficially used. And, how can we effectively address and prevent negative impacts from biosolids pollutants as we seek to increase beneficial reuse?

The next blog in this series will consider the broader federal regulatory history of biosolids, before more specifically focusing on how and when PFAS were identified as biosolids pollutants and more recent/potential federal actions. Subsequent work will highlight state-level experiences and efforts, including in New York, to address PFAS in biosolids.

ABOUT THE AUTHORS

Francis Ofori-Awuku is a graduate research assistant at the Rockefeller Institute of Government and a PhD student in the Department of Environmental Health Sciences at the School of Public Health, University at Albany (SUNY)

Laura Rabinow is deputy director of research at the Rockefeller Institute of Government

Annabelle Trowbridge is formerly an undergraduate research assistant at the Rockefeller Institute of Government and a student at the University at Albany (SUNY)

[1] The EPA collects annual biosolids reports from (approximately 2,500) Publicly Owned Treatment Works (POTWs) that:

- serve 10,000 people or more;

- are Major POTWs (POTWs with a design flow rate greater than or equal to one million gallons per day);

- are Class 1 management facilities (POTWs with an approved pretreatment program or facilities that have been classified as such by the EPA or state); or

- are otherwise required to report by EPA or permitting authority.

[2] The EPA’s Office of Inspector General (OIG) also estimated in a 2018 report that 47 percent of biosolids generated by major publicly owned treatment works in the US were applied to land for soil productivity and plant growth.

[3] The plan also notes state actions with respect to addressing PFAS in biosolids, which will be further discussed in a subsequent blog of this series.